2025superior products | Hedge Cams Series

Back Time:2025-04-16 Views:54 Source:Wuhan IEM Precision Technology Co.,LTD

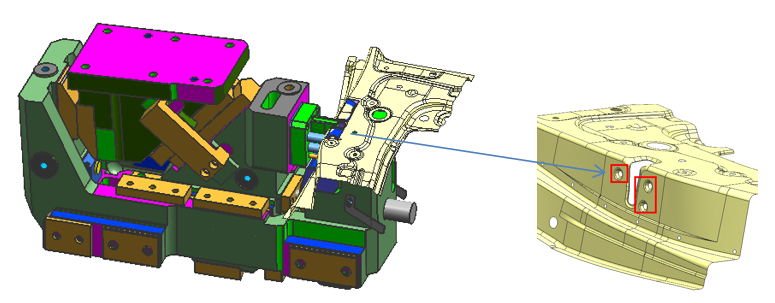

In order to solve the parts with negative Angle direction punching shaping, such as the following figure with negative Angle parts punching shaping. Our new development of offset wedge, mainly for negative Angle parts punching and shaping work.

How it works

The wedge is divided into four parts: drive block, working slider, guide slider, and base. The downward movement of the driving block drives the working slider A to move to the right, and the guide slider B to move to the left, so that the working slider A and the guide slider B move in the opposite direction, so as to ensure that the negative Angle of the parts can be blanked and the negative Angle parts can be freely removed after blanking. It is specially designed to solve the negative Angle parts, carry out unified standardized design, serial development, so that it is more practical, avoid the non-standard custom diagonal wedge design cycle is long, difficult to produce and other problems, with the following characteristics.

Detailed product information can be found in the 2024 product catalog

Blanking smooth

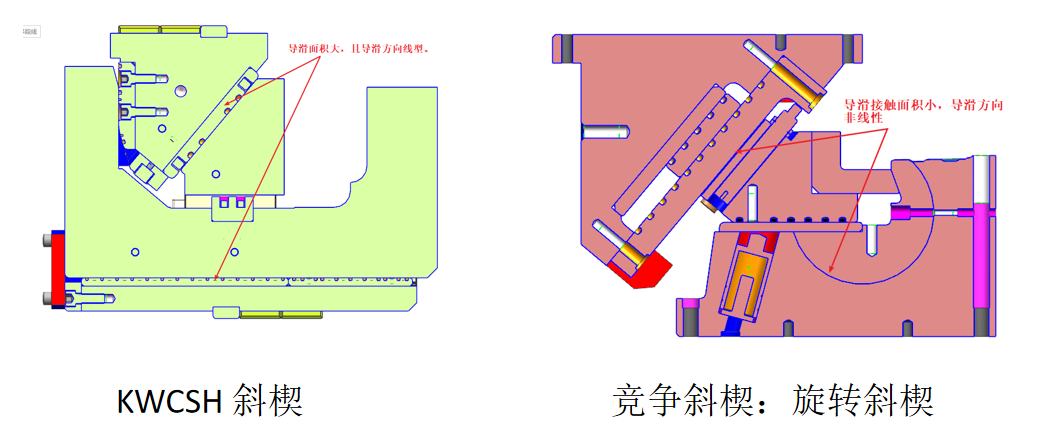

1. Large sliding contact area, linear blanking direction, more stable blanking.

2. compared with the same specifications of rotary wedge, guide sliding contact area is large, punching direction linear, punching more stable.

Slider mounting surface can be changed

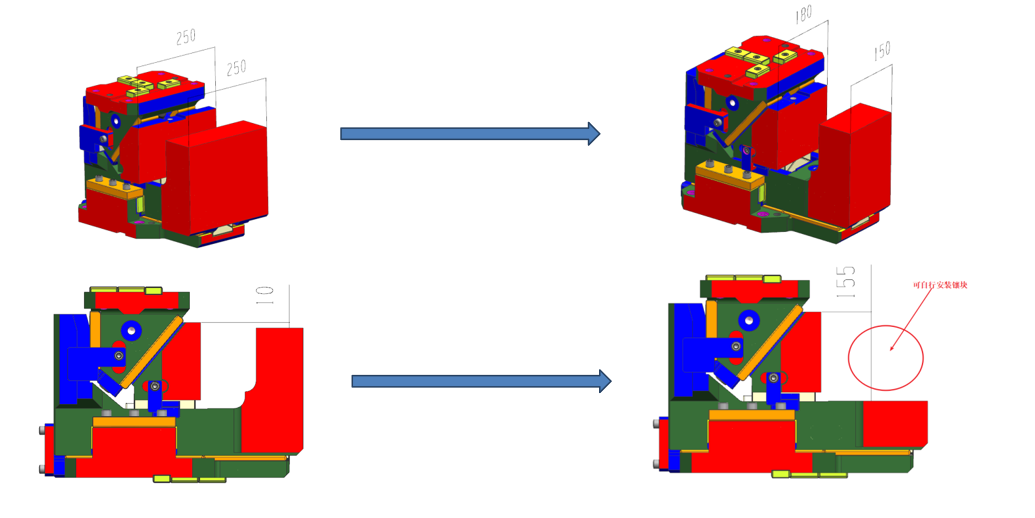

1. can be processed in the installation surface body, can also be directly installed in the surface insert.

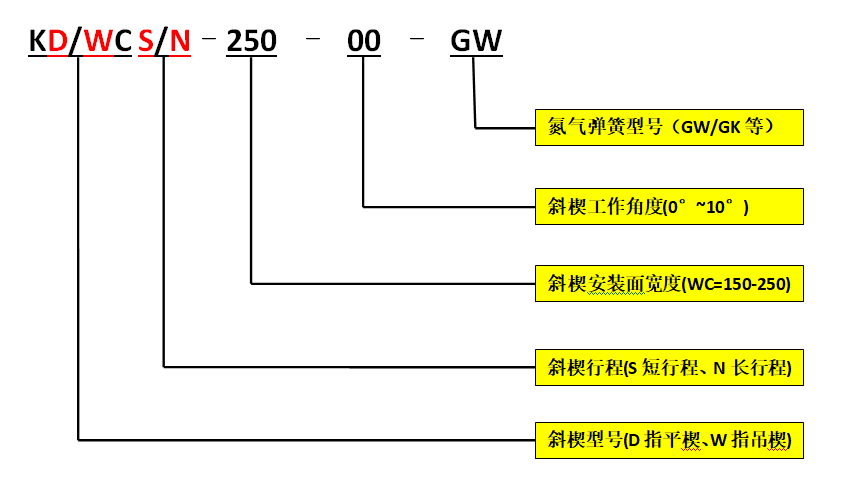

2. the slider mounting surface can be changed, the width of the working slider A can be changed to 180-250, the width of the guide slider B can be changed by 150-250, and the height can be changed by 10-155. The guide slider B mounting surface can be machined into a mold surface, or the insert and other components can be installed by themselves.

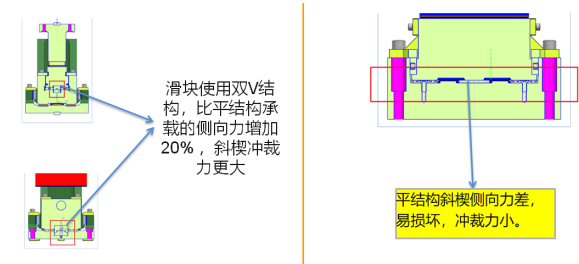

High stability, high load

1. V-shaped structure is used in the guiding direction, which has strong lateral force and high stability.

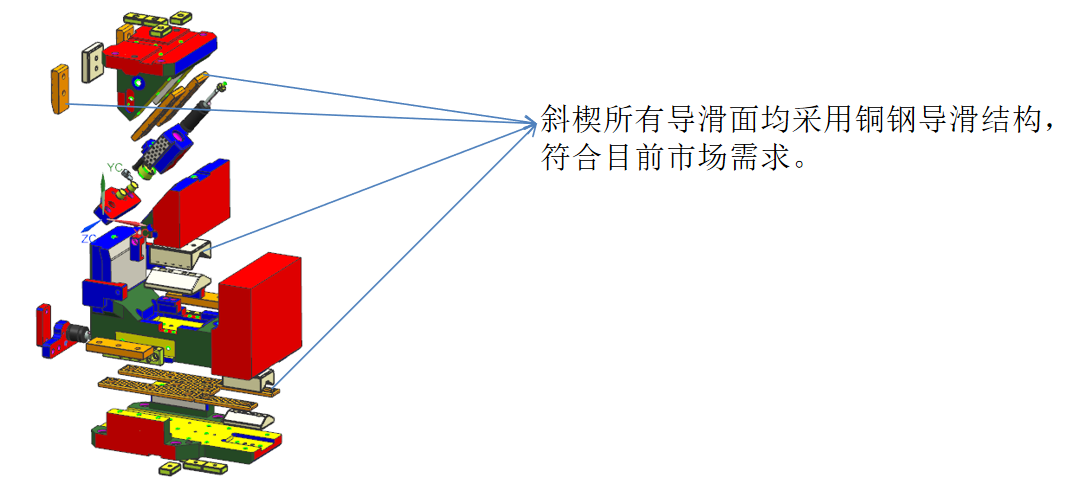

Monolithic copper-steel against grinding

1, between the base and the slider, the slider and the drive are made of copper to steel sliding guide, good wear resistance, long life of the wedge

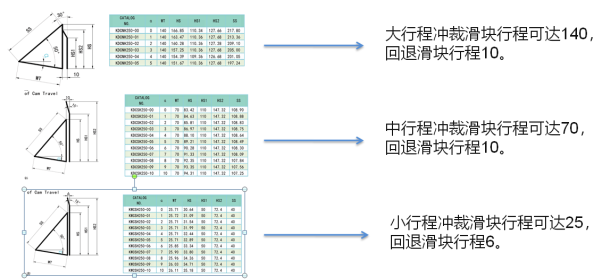

1. the oblique wedge working stroke three gears, a wider range of adaptation.

2. KWCSH diagonal wedge working stroke is 25mm, KDCSH working stroke is 70, KDCNH working stroke is 140.

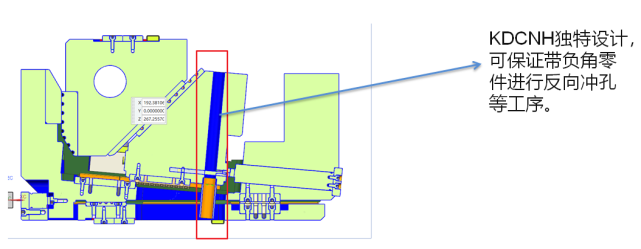

Backpunching

1. KDCNH wedge has reverse punching and discharging ability.

In the field of industrial manufacturing with high efficiency and high precision requirements, high-quality mold standard products are undoubtedly an indispensable partner for automotive molds. We know the importance of delivery time to users, has been committed to providing short delivery time, high quality, easy installation, easy maintenance of products, help mold design is simpler, mold manufacturing is faster, mold maintenance is more convenient. Thank you for your attention, we look forward to working with you to create a better future!